Pipe Bursting / Splitting

At Olsen, we offer a “rig and operator” on a hire basis, or pipe bursting at a contract price.

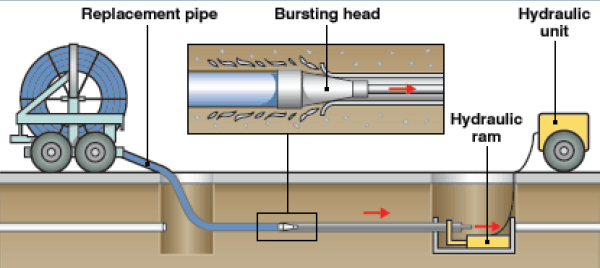

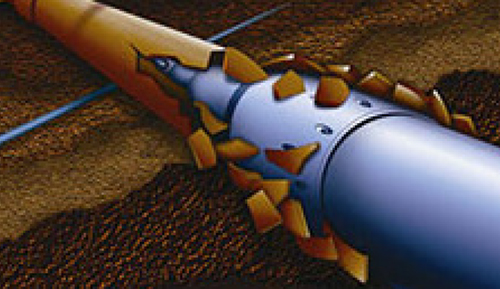

“Pipe Bursting”, or “mains Bursting” is used to break out an existing cast iron, concrete, or clay pipe to allow insertion of a new pipe of a similar, or larger diameter.

“Pipe Splitting” or “Mains Splitting” is used to “Split” and open a seam in a steel or ductile iron pipe, again to allow insertion of a new size for size, or larger pipe.

The main difference between the two methods is the magnitude of force required to “split” as opposed to burst”, and in some instances, different equipment to facilitate the split.

Bursting and Splitting are mostly employed by companies in the gas, water and drainage industries.

Bursting projects vary in length from 10 – 150m, and in diameter from 3” up to 18”

We use “rod winches” for mains bursting, where lengths of steel rod are joined together to form a continuous string and pushed through the existing pipe. The string is then pulled back through the pipe, along with a knife / expander combination, splitting or bursting out the existing pipe and pulling the new pipe in behind.

Call or e-mail us for your pipe bursting requirements.